Sliding axle isolation plates - what softbooters need to know

@wild-cherry hey James - I watched the super technical video - really well put together.

my idea is probably not unique - multiple thin shims stacked together (anti-rotation grooves like F2 would keep them in orbit place) 2.5 deg cant wedges and 3 degree lift wedges - able to stack 4 wedges for a cant of 5 degrees and lift of 6 degrees. Each wedge has the exact same perimeter shape - something that would fit fit most softboot bindings. Probably the thinnest edge would have to be 1/8” - so the stack of 4 would be 1/2” in one corner. Material would be non-structural plastic. Mounting is the tricky part - I envision using lugs that go into the inserts through 4 curved slots in the wedges - these would allow biding rotation - there would be some blackout angles though. The lugs are load pass though and would come in different lengths (color coded) and would have threaded inserts in them. Tightening them to the board via a wide flat screwdriver.

can you get a vision of this system? The idea would be to package in pairs and not make them too heavy or rigid - do you think there should be more options on the angles?

@rocketman69 Yeah, I think I get the picture.

Question: how do the lugs work across different cant and lift angles? Once you add any cant or lift the binding baseplate is no longer parallel to the board's topsheet and so the binding mounting screws aren't in line with the board's inserts anymore. So how do you account for the change in angle and how do you make one set of lugs work for different cant and lift options?

Your profile has you occupation listed as "aerospace engineer" so I'm sure you've considered this, I'm just not seeing it in your description. So will your design work with any binding or are the wedges part of a whole new binding design?

I'm just slaying...

@wild-cherry possibly would require a unique disk with curved pockets for the ball screws to rotate in - this may be impractical if different binding manufacturers have different disk insert sizes.

I found fellow enthusiasts on this page from Japan, and I’m posting this with tears of joy.

Hello, please call me spar. I'm 25yo

I own a Boiler custom plate (for freestyle) and a Jasey-Jay 914 plate (the same one that Wild-Cherry has).

Both plates share a floating carbon structure, but in terms of vibration damping and board performance, I believe the JJA plate is superior. The two “horns” on the nose side not only absorb vibrations but also flex along with the board’s bending. As the turn progresses, the plate’s restoring force adds to the board’s flex, generating an explosive ride.

The Boiler plate provides excellent vibration damping from the rider’s perspective, but in reality, you can notice the board moving erratically underneath it. It also requires extremely precise setup, which is so tedious that once installed, you never want to remove it again (a cursed piece of equipment, haha). On the other hand, the JJA plate is designed with a comfortable margin for error, making setup much less sensitive. Some people might find the creaking sound during riding a bit annoying, but applying a thin layer of grease should help.

Plates make it easier to turn regardless of snow conditions, but you have to be mindful of lift fatigue due to the added weight and the reduced feel of the snow surface. Last season, I was riding a JJA plate with a TBX164 in soft conditions, and my board snapped when the nose got stuck in a deep rut…

I’m also very interested in canting.

Actually, I love snowboard gear so much that I started working for a Japanese brand called ALC Snowboards in February. I’m hoping to develop a flexible lift cant system based on our alpine binding structure. Of course, I also want to create a single-piece plate for freestyle use. Since we have a large CNC machine for aluminum milling, I’d like to start testing prototypes for the next season.

@spar_snb Hello Spar - welcome to the Forum. You have an amazing collection of boards - how is your season going? I’m in Colorado and having a fun season working on making big turns and deep trenches (I’m a big guy😎).

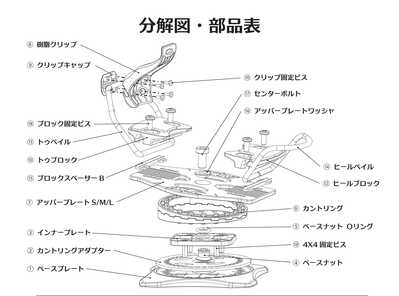

Thanks for posting the hardboot bindings iso drawing - so interesting 👍 I ride on F2 Intech bindings - they’re so easy to get in/out of. I’m 65 and my tummy gets in the way of bending over 😎🤣😢. Does your company sell this binding into the US? I love the dual canted notched rings - very clever design. I hope we can chat about binding designs. My name in Greg

Hello! Mr. Rocketman,

I’m glad to talk about ALC bindings! However, we don’t manufacture Intec heel parts…

This is mainly due to the recent popularity of yellow boots and the fact that our company specializes in machining. Because of the way Intec heel parts endure stress, they need to be forged or bent rather than machined to maintain their strength.

However, our company president was originally a Catec rider, so ALC bindings should be compatible with Catec heel blocks (the screw pitch should match). Please note that this is not an official statement!

If you need more information, it would be great to get in touch somehow… But I don’t want to go too far off-topic in this thread.

@spar_snb Your second plate that you call a Boiler, is not a Bomber Boiler plate (a design and product by Finn Doyle from the USA). Not sure exactly what design it is but it looks to be using AllFlex pattern inserts or similar.

Without knowing how the board interfaces with the plate and copes with the board flexing in use, and where the bindings are mounted in relation to the axles. it is hard to judge how well a design might work.

Hello, riotsupercarver!

The plate I’ve attached here is the one I refer to as the “Boiler.” I acquired it secondhand, but it’s a 24 cm wide floating plate that uses the same mounting base as the alpine-type version. I believe this is a freestyle version of the Boiler plate, which was produced in very limited quantities.

Personally, I like my board to flex deeply, so I set the mounts as short as possible. As mentioned in some manuals, I position the

rear axle so that it sits directly under the rear foot binding. For the front, I keep the mount relatively short as well, but wide enough to install securely.

@spar_snb

Thanks for the clarification and info. That certainly looks like a Bomber Boiler plate, just in a custom variant I wasn't aware had been made.

I'm intrigued by the isolation plates on the other 2 boards in the photo. Their design is also new to me. Manufacturer +/- website links?

I had no idea a freestyle version of the Boiler plate existed until I got my hands on one myself. It’s probably extremely rare. The setup is quite tricky—Jasey even said, “If you’re going to use that, let us build one for you—just please don’t use it!”

Boiler plates are great for reducing physical strain when carving on rough surfaces, but I don’t feel they enhance carving depth or speed. JJA’s plates, on the other hand, are truly excellent.

The plates in the photo are from a Japanese manufacturer called ALC: https://alc-snow.jp/

I’ve been working there since February.

What you’re seeing are two prototypes of the RC15. The front and rear blocks are fixed with pins, and a carbon shaft connecting the metal plates slides in response to board flex, making it a type of floating plate.

The key feature is that the number of carbon shafts can be changed. By adjusting both the number and position, you can tune the flex and torsion characteristics.

If you’re curious about anything else regarding ALC’s products, feel free to ask!

@spar_snb_snb Presumably you have the 4x4 mount for your Boiler Plate? That is quite tricky to use. Its interaxle distance will be pretty short compared to your ALC plates (and other AllFlex mount plates).

That ALC plate design is an interesting solution to the problem of the distance between the hinges shortening as the board flexes.

I can see some advantages - long interaxle distance, tunable torsion control, all the mounting screws immediately visible and accessible.

Other features: stabilising bar is bolted to the board, thus when board flexes so do the carbon rods flex and the bindings tilt. This may reduce bump absorption. A free floating stabiliser bar, with grub screws to attach it to the carbon rods would allow the plate to stay flatter while the board flexed.

How is friction minimised between the rods and the walls of the tunnels within which they slide? I can see from the website that the ends of the rods have a different surface treatment compared to the middle.

Please correct me if my interpretation of the photos on the ALC website is incorrect.

I've also just added ALC to our worldwide list of carving snowboard manufacturers at AlpineSnowboarder.com Forums. Given that it makes boards, bindings, and plates there's likely to be significant interest in looking at its products.

Just watched the ALC binding setup video.

If you are working for them you might want to show them this video which I made about binding stance, lift, and cant. While much is similar we have different views on the use of cant, lateral binding tilt.

Thanks for checking out the ALC website!

Actually, until recently there was no English content at all, so I’ve been slowly working on adding English support myself.

On the RC15 plate, there’s about 1 cm of clearance within the structure to allow the rods to move freely.

We tested reducing this clearance to zero, but the board became incredibly stiff. On this plate, the blocks at both ends do not slide—they act purely as hinges. As a result, when the board flexes too much, the rods hit their limit and “lock,” stopping further movement.

The stabilizer increases both response and flex stiffness, but as you rightly noted, it also reduces the floating feel of the plate. That’s why we’re currently working on two new concepts: the “Bridge” and the “Spring Stabilizer.”

The Bridge is a part that applies pressure only in the deck direction, preserving the floating feel at the start of a turn while suppressing board flex during the turn itself.

The Spring Stabilizer has a built-in spring, giving it a range of motion. This allows the carbon rods to flex naturally, and when the spring compresses fully, the stabilizer then engages fully.

Both of these concepts are still in testing, but we’ve been getting some very promising results in terms of ride feel.

The darker section on the ends of the rods is where the surface has been slightly shaved. The tunnels inside the plate are machined to very tight tolerances to match this shaved portion, which intentionally creates some friction. A thin layer of grease is applied during assembly to allow smoother movement.

Thanks also for adding ALC to the AlpineSnowboarder forum—that’s super helpful. I was actually planning to reach out to the site, so your support really saves me a step.

Right now, Nevin Galmarini is testing one of our plates, and we’re hoping to develop some exciting new products from this collaboration.

Personally, since I’ve spent about 90% of my snowboarding life on freestyle boards, I’m also really hoping to develop a floating plate specifically for freestyle use.

Been using the Translate function in my Firefox browser to view the ALC site.

When the board flexes into an arc below the plate, the chord distance between the attachment points shortens, but by a remarkably small amount. The math is not too hard to do. When I built my own sliding axle plates I needed deal with around 0.7cm shortening. With a longer interaxle distance the change will be a little larger.

Do the holes in the plate ends that the rods slide in have air vents of some kind to allow air movement in and out as the end cavity volume changes? A longitudinal slot in the side of the rods would achieve the same result. (Just watched the video in your reply above and seen the vent holes in the plate)

The AllFlex plate functions as a board flex modifier. What is thought to be the benefit of modifying the flex of the board when flex characteristics can be built in at board construction? Is it just fine tuning of board flex to an individual rider's mass and style?

The ALC bindings look a little like Catek bindings with that single central bolt holding the binding plate. The baseplate is apparently 5mm thick hardened aluminium alloy. I, and a number of other riders, have metal fatigue fractured the Bomber TD3 binding plate which is a design with a much shorter leverage when in use. I run a mondo 29 UPZ boot and would need the large ALC base plate. If ALC wants any European market penetration the Large baseplate will have to go back into production.

Plates made from a single piece of metal like the Allflex or Ironrock function by remaining in a floating state—dampening vibration—within the hinge movement range, without affecting the board’s flex or torsion. However, once the hinges reach their travel limit in either direction, the stiffness of the top plate itself provides a significant increase in stability. To put it simply, one of the advantages of these systems is that they introduce a two-stage flex behavior when mounted on a board. This is especially effective in racing scenarios.

On the other hand, ALC plates are designed to follow the board’s movement by varying the number of carbon shafts from 3 to 13, utilizing the stiffness and resilience of the shafts themselves. I believe this provides both stability and maneuverability, especially for freecarving applications where extreme responsiveness isn’t necessarily required. (Of course, it’s also true that we don’t yet have access to feedback from overseas snow conditions or World Cup-level racing.) Nevin also gave high praise to the plate specifically for freecarving use.

As for ALC bindings, it’s no exaggeration to say they were inspired by Catek bindings—our company president was a long-time Catek rider (unofficially, the toe and heel blocks from Catek could be mounted on the ALC baseplate).

A mondo 29 UPZ boot is a size I’ve rarely seen here in Japan. In fact, the Large baseplate does exist, but due to extremely low domestic demand (this season’s binding preorders were 60% Small, 40% Medium), we’ve removed it from next season’s catalog. Personally, I ride a Track 425 Pro in 27cm, and I use the Small baseplate. With centering adjustments that include the baseplate itself, it works fine. Depending on your sole length, the Medium might work, but for riders who haven’t yet finalized their stance position, I’d recommend going with the suggested size to start.

Fascinating stuff. Designing the spring stabiliser so that the point at which it starts bending the rods varies gives another way of tuning the overall flex.

The AllFlex plate has mid board linkages that prevent the distance between plate and board exceeding 6.25mm if my memory serves me well. From then on plate and board will both have to bend for more board flex to occur.

- 21 Forums

- 227 Topics

- 2,206 Posts

- 2 Online

- 511 Members