Posted by: @angry4nusIs there a delay in shipping? I purchased a set 2 wks ago

You should have those by now for sure. I'll look into it this afternoon @angry4nus

I'm just slaying...

Hey, could help look into my order too? I haven't received any update on it [Order #3421] (February 8, 2025) Thanks @wild-cherry

@haipeng-zhang Everything is shipping Thursday! Sorry about the delay, I just couldn't keep up and I had to let some things slide for a couple of weeks. I just got home last night (from Montucky and Utah), I'm catching up on everything now.

I'm just slaying...

I don't understand what prevents these risers from slipping out of the bindings when used in the wider settings. It seems like they are held in place only by friction, and they could be lost while riding.

Do you sell replacement posts?

Is it possible to use the wings with hard boot bindings like F2s?

@wild-cherry Just wondering, since the material is already being machined, how much, if any, support would be lost by beveling the side of the wing facing the edge to be roughly the same angle as the bevel on the board?

@wild-cherry Here's a design idea to make the wings adjustable for 250mm width boards.

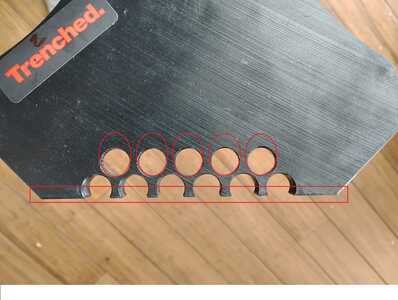

Remove 5mm from the inside edge of each wing. Make the holes 5mm longer allowing for lateral adjustment before tightening the binding down.

Question is how would this affect the engineering requirements having longer holes and less material for the pins with wide board width setups?

Posted by: @dicynodontI don't understand what prevents these risers from slipping out of the bindings when used in the wider settings. It seems like they are held in place only by friction, and they could be lost while riding.

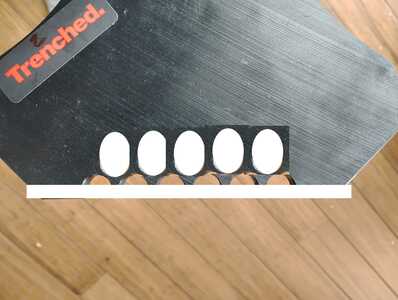

I ride them exclusively in this setting and haven't had any sliding. The risers are 1mm thinner than the post, so there's a lot of friction there when the bindings are tightened up. I might adjust that for next season's wings anyway though, maybe even make two sizes to fit more boards, or use slots instead of holes for more adjustability. New prototypes are printing this week.

Posted by: @ruebeesDo you sell replacement posts?

Can do, yes. Or you can buy them and make your own risers. Just make sure they're thicker than the height of the post... Email me at [email protected]

Posted by: @ruebeesIs it possible to use the wings with hard boot bindings like F2s?

Nope, too narrow for sure. The F2s have a lot of lift already, you can order extra shims from them too (or make your own).

Posted by: @angry4nusI did have some rotation of the plates while riding.

Good to know, thanks.

Posted by: @jeffgJust wondering, since the material is already being machined, how much, if any, support would be lost by beveling the side of the wing facing the edge to be roughly the same angle as the bevel on the board?

Good question. I transferred out of the engineering department at university after just one year, so... I don't know. Seems like a good idea though, it would cause less drag.

The design could be adjusted for sure but it looks like we're probably going with a different manufacturing process for the next batch. I should have some photos next week. I don't know what it's called but it's like a 3D printed lattice matrix that cures under UV light. Prototypes are printing now. We'll probably have to make some adjustments to fine tune the flex and damping properties but I think this could be better than machining or injection molding. We lose the trampoline entirely, but the flex could be more progressive and different materials (and matrix layouts) will yield different damping properties.

Thanks to all of you for the feedback and your continued support, it's much appreciated!

In a way, the whole fist run of wings were prototypes and all the buyers are also inadvertent gear testers. We ran though a lot of designs and prototypes but no one actually rode these before they went up for sale. I'm proud to say though that there was zero breakage and zero returns this season (so far). And rest assured, I had already been using posts from that same batch for four seasons (they are Jasey Jay's posts), and we copied the shape and adjusted the flex to match Jasey Jay's butterfly risers so I knew it was already optimized or very close and that this version would be an improvement on his well tested designs.

I'm just slaying...

Posted by: @jeffgRemove 5mm from the inside edge of each wing. Make the holes 5mm longer allowing for lateral adjustment before tightening the binding down.

You read my mind, brother. See above. (Seems I was writing that post while you were writing yours...)

I want the slots a bit wider too so the wings are easier to rotate and line up with the edges. For the first set, we're just testing the matrix printing method first.

I'm just slaying...

@ruebees I did use the risers with my F2 Titanium bindings on my Stranda Cheater using the narrow settings. Worked great and showed me what that board can really do. I have them half staggered - toe side on middle position - heel side on rearward position.

Posted by: @wild-cherry

The design could be adjusted for sure but it looks like we're probably going with a different manufacturing process for the next batch. I should have some photos next week. I don't know what it's called but it's like a 3D printed lattice matrix that cures under UV light. Prototypes are printing now. We'll probably have to make some adjustments to fine tune the flex and damping properties but I think this could be better than machining or injection molding. We lose the trampoline entirely, but the flex could be more progressive and different materials (and matrix layouts) will yield different damping properties.

With 3D printing you can really play around with material density distribution and use the orientation of the material to create the stiffness and flex you want, in the direction you want. At the same time you can make geometries with 3D print that are not possible or very expensive with traditional machining.

At the same time it is very fast to make prototypes and test stuff out.

I see a lot of potential.

I made my own canted risers for the Flow NX2 binding, designed, printed and tested in 24 hours.

Posted by: @carvehardI made my own canted risers for the Flow NX2 binding, designed, printed and tested in 24 hours.

Really? How did you manage the interface? Flat risers are easy but with the canting you need to mount the binding to something metal right? Share some pictures?

I'm just slaying...

- 21 Forums

- 227 Topics

- 2,206 Posts

- 0 Online

- 511 Members